Page 15 - Steel Tech India eMagazine Volume April 2022

P. 15

VOL. 16 • NO. 3 • April 2022

While some plants majorly adopted ladle treatment for medium pressure to augment slag/ metal reaction

reducing P by building a highly basic slag with higher Sample analysis and continuation of process as needed

FeO contents, some desulphurisationhappened as well

due to the final reducing slag build up after deoxidation De slagging and Al /c/Alloy addition based on sample

of the bath when the FeO content of the slag is reduced analysis

to a large extent favouring desulphurisation. lime/synthetic slag addition

0

tap from IF at nearly 1600 c Slag skimming/drain out Sample analysis/trimming addition/temperature

before tapping

adjustment

Target tap chemistry C 0.10 max Mn< 0.05 Si /Al Nil transfer to caster

ladle addition- lime/ Mill Scale/Fluorspar - On line the total treatment time from IF tapping to transfer to

Purging caster varies from 60 to 75 minutes but does not impact

Arcing and further lime/ mill scale addition- Purging at sequence casting continuity.

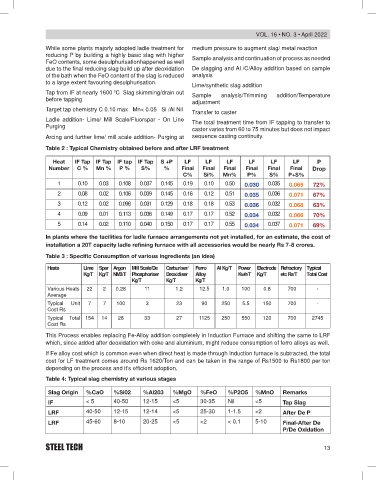

Table 2 : Typical Chemistry obtained before and after LRF treatment

Heat IF Tap IF Tap IF tap IF Tap S +P LF LF LF LF LF LF P

Number C % Mn % P % S% % Final Final Final Final Final Final Drop

C% Si% Mn% P% S% P+S%

1 0.10 0.03 0.108 0.037 0.145 0.19 0.10 0.50 0.030 0.035 0.065 72%

2 0.08 0.02 0.106 0.039 0.145 0.16 0.12 0.51 0.035 0.036 0.071 67%

3 0.12 0.02 0.098 0.031 0.129 0.18 0.18 0.53 0.036 0.032 0.068 63%

4 0.09 0.01 0.113 0.036 0.149 0.17 0.17 0.52 0.034 0.032 0.066 70%

5 0.14 0.02 0.110 0.040 0.150 0.17 0.17 0.55 0.034 0.037 0.071 69%

In plants where the facilities for ladle furnace arrangements not yet installed, for an estimate, the cost of

installation a 20T capacity ladle refining furnace with all accessories would be nearly Rs 7-8 crores.

Table 3 : Specific Consumption of various ingredients (an idea)

Heats Lime Spar Argon Mill Scale/De Carburiser/ Ferro Al Kg/T Power Electrode Refractory Typical

Kg/T Kg/T NM3/T Phosphoriser Deoxidiser Alloy Kwh/T Kg/T etc Rs/T Total Cost

Kg/T Kg/T Kg/T

Various heats 22 2 0.28 11 1.2 12.5 1.0 100 0.8 700 -

Average

typical Unit 7 7 100 3 23 90 250 5.5 150 700 -

cost Rs

typical total 154 14 28 33 27 1125 250 550 120 700 2745

cost Rs

this Process enables replacing Fe-Alloy addition completely in Induction Furnace and shifting the same to lRF

which, since added after deoxidation with coke and aluminium, might reduce consumption of ferro alloys as well.

If Fe alloy cost which is common even when direct heat is made through Induction furnace is subtracted, the total

cost for lF treatment comes around Rs 1620/ton and can be taken in the range of Rs1500 to Rs1800 per ton

depending on the process and it’s efficient adoption.

Table 4: Typical slag chemistry at various stages

Slag Origin %CaO %Si02 %Al203 %MgO %FeO %P2O5 %MnO Remarks

IF < 5 40-50 12-15 <5 30-35 Nil <5 Tap Slag

LRF 40-50 12-15 12-14 <5 25-30 1-1.5 <2 After De P

LRF 45-60 8-10 20-25 <5 <2 < 0.1 5-10 Final-After De

P/De Oxidation

Steel tech 13