Page 25 - Steel Tech India eMagazine Volume October 2023

P. 25

92/ Ć ,668( Ć 2FWREHU

D E

)LJ D 1DUURZ JDS IRUPHG EHIRUH IXOO PHOWLQJ DW KLJKHU (5: SRZHU UDQJH E /RUHQW] IRUFHV DFWLQJ RQ WKH HGJH ZDOO

DW WKH DUFLQJ DQG WKH HOHFWURPDJQHWLF IRUFH VWDUWV WR

DFW EHKLQG WKH EULGJH 7KH EULGJH VWDUWV WR PRYH ZLWK

WKH HOHFWURPDJQHWLF IRUFH DQG PROWHQ PHWDO VWDUWV WR

PRYH YLD FDSLOODU\ DFWLRQ DQG WKH\ PHHW DW WKH PLGGOH

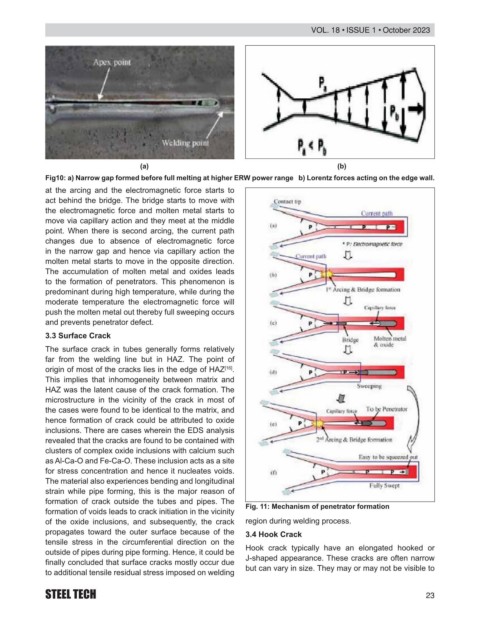

point. When there is second arcing, the current path

FKDQJHV GXH WR DEVHQFH RI HOHFWURPDJQHWLF IRUFH

in the narrow gap and hence via capillary action the

PROWHQ PHWDO VWDUWV WR PRYH LQ WKH RSSRVLWH GLUHFWLRQ

7KH DFFXPXODWLRQ RI PROWHQ PHWDO DQG R[LGHV OHDGV

WR WKH IRUPDWLRQ RI SHQHWUDWRUV 7KLV SKHQRPHQRQ LV

SUHGRPLQDQW GXULQJ KLJK WHPSHUDWXUH ZKLOH GXULQJ WKH

PRGHUDWH WHPSHUDWXUH WKH HOHFWURPDJQHWLF IRUFH ZLOO

SXVK WKH PROWHQ PHWDO RXW WKHUHE\ IXOO VZHHSLQJ RFFXUV

DQG SUHYHQWV SHQHWUDWRU GHIHFW

6XUIDFH &UDFN

7KH VXUIDFH FUDFN LQ WXEHV JHQHUDOO\ IRUPV UHODWLYHO\

IDU IURP WKH ZHOGLQJ OLQH EXW LQ +$= 7KH SRLQW RI

> @

RULJLQ RI PRVW RI WKH FUDFNV OLHV LQ WKH HGJH RI +$= .

7KLV LPSOLHV WKDW LQKRPRJHQHLW\ EHWZHHQ PDWUL[ DQG

+$= ZDV WKH ODWHQW FDXVH RI WKH FUDFN IRUPDWLRQ 7KH

PLFURVWUXFWXUH LQ WKH YLFLQLW\ RI WKH FUDFN LQ PRVW RI

WKH FDVHV ZHUH IRXQG WR EH LGHQWLFDO WR WKH PDWUL[ DQG

KHQFH IRUPDWLRQ RI FUDFN FRXOG EH DWWULEXWHG WR R[LGH

inclusions. There are cases wherein the EDS analysis

UHYHDOHG WKDW WKH FUDFNV DUH IRXQG WR EH FRQWDLQHG ZLWK

FOXVWHUV RI FRPSOH[ R[LGH LQFOXVLRQV ZLWK FDOFLXP VXFK

DV $O &D 2 DQG )H &D 2 7KHVH LQFOXVLRQ DFWV DV D VLWH

IRU VWUHVV FRQFHQWUDWLRQ DQG KHQFH LW QXFOHDWHV YRLGV

7KH PDWHULDO DOVR H[SHULHQFHV EHQGLQJ DQG ORQJLWXGLQDO

VWUDLQ ZKLOH SLSH IRUPLQJ WKLV LV WKH PDMRU UHDVRQ RI

IRUPDWLRQ RI FUDFN RXWVLGH WKH WXEHV DQG SLSHV 7KH

IRUPDWLRQ RI YRLGV OHDGV WR FUDFN LQLWLDWLRQ LQ WKH YLFLQLW\ )LJ 0HFKDQLVP RI SHQHWUDWRU IRUPDWLRQ

RI WKH R[LGH LQFOXVLRQV DQG VXEVHTXHQWO\ WKH FUDFN region during welding process.

SURSDJDWHV WRZDUG WKH RXWHU VXUIDFH EHFDXVH RI WKH +RRN &UDFN

WHQVLOH VWUHVV LQ WKH FLUFXPIHUHQWLDO GLUHFWLRQ RQ WKH

RXWVLGH RI SLSHV GXULQJ SLSH IRUPLQJ +HQFH LW FRXOG EH +RRN FUDFN W\SLFDOO\ KDYH DQ HORQJDWHG KRRNHG RU

¿QDOO\ FRQFOXGHG WKDW VXUIDFH FUDFNV PRVWO\ RFFXU GXH - VKDSHG DSSHDUDQFH 7KHVH FUDFNV DUH RIWHQ QDUURZ

WR DGGLWLRQDO WHQVLOH UHVLGXDO VWUHVV LPSRVHG RQ ZHOGLQJ EXW FDQ YDU\ LQ VL]H 7KH\ PD\ RU PD\ QRW EH YLVLEOH WR

STEEL TECH