Page 23 - Steel Tech India eMagazine Volume October 2023

P. 23

92/ Ć ,668( Ć 2FWREHU

)LJ D 3KRVSKRUXV FRQWHQW QHDU WKH ZHOG UHJLRQ GXH WR FHQWUH OLQH VHJUHJDWLRQ E )DLOXUH DW WKH ZHOG UHJLRQ GXH WR

KLJKHU SKRVSKRUXV FRQWHQW

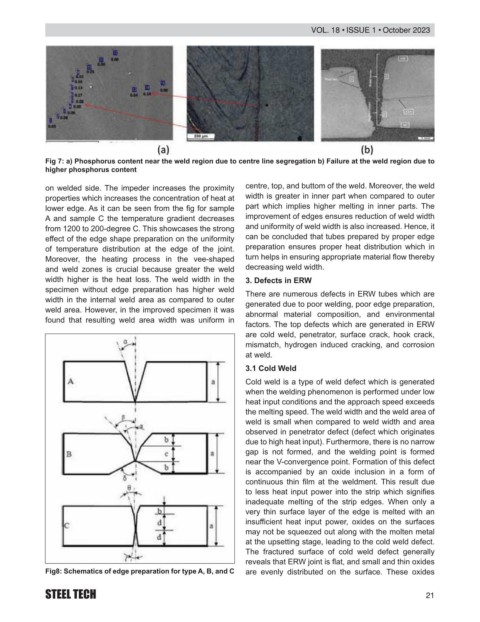

RQ ZHOGHG VLGH 7KH LPSHGHU LQFUHDVHV WKH SUR[LPLW\ FHQWUH WRS DQG EXWWRP RI WKH ZHOG 0RUHRYHU WKH ZHOG

SURSHUWLHV ZKLFK LQFUHDVHV WKH FRQFHQWUDWLRQ RI KHDW DW ZLGWK LV JUHDWHU LQ LQQHU SDUW ZKHQ FRPSDUHG WR RXWHU

ORZHU HGJH $V LW FDQ EH VHHQ IURP WKH ¿J IRU VDPSOH SDUW ZKLFK LPSOLHV KLJKHU PHOWLQJ LQ LQQHU SDUWV 7KH

$ DQG VDPSOH & WKH WHPSHUDWXUH JUDGLHQW GHFUHDVHV LPSURYHPHQW RI HGJHV HQVXUHV UHGXFWLRQ RI ZHOG ZLGWK

IURP WR GHJUHH & 7KLV VKRZFDVHV WKH VWURQJ DQG XQLIRUPLW\ RI ZHOG ZLGWK LV DOVR LQFUHDVHG +HQFH LW

HႇHFW RI WKH HGJH VKDSH SUHSDUDWLRQ RQ WKH XQLIRUPLW\ can be concluded that tubes prepared by proper edge

RI WHPSHUDWXUH GLVWULEXWLRQ DW WKH HGJH RI WKH MRLQW preparation ensures proper heat distribution which in

0RUHRYHU WKH KHDWLQJ SURFHVV LQ WKH YHH VKDSHG WXUQ KHOSV LQ HQVXULQJ DSSURSULDWH PDWHULDO ÀRZ WKHUHE\

DQG ZHOG ]RQHV LV FUXFLDO EHFDXVH JUHDWHU WKH ZHOG decreasing weld width.

width higher is the heat loss. The weld width in the 'HIHFWV LQ (5:

VSHFLPHQ ZLWKRXW HGJH SUHSDUDWLRQ KDV KLJKHU ZHOG 7KHUH DUH QXPHURXV GHIHFWV LQ (5: WXEHV ZKLFK DUH

ZLGWK LQ WKH LQWHUQDO ZHOG DUHD DV FRPSDUHG WR RXWHU generated due to poor welding, poor edge preparation,

ZHOG DUHD +RZHYHU LQ WKH LPSURYHG VSHFLPHQ LW ZDV DEQRUPDO PDWHULDO FRPSRVLWLRQ DQG HQYLURQPHQWDO

IRXQG WKDW UHVXOWLQJ ZHOG DUHD ZLGWK ZDV XQLIRUP LQ

IDFWRUV 7KH WRS GHIHFWV ZKLFK DUH JHQHUDWHG LQ (5:

DUH FROG ZHOG SHQHWUDWRU VXUIDFH FUDFN KRRN FUDFN

PLVPDWFK K\GURJHQ LQGXFHG FUDFNLQJ DQG FRUURVLRQ

at weld.

&ROG :HOG

Cold weld is D W\SH RI ZHOG GHIHFW ZKLFK LV JHQHUDWHG

ZKHQ WKH ZHOGLQJ SKHQRPHQRQ LV SHUIRUPHG XQGHU ORZ

heat input conditions and the approach speed exceeds

WKH PHOWLQJ VSHHG 7KH ZHOG ZLGWK DQG WKH ZHOG DUHD RI

ZHOG LV VPDOO ZKHQ FRPSDUHG WR ZHOG ZLGWK DQG DUHD

REVHUYHG LQ SHQHWUDWRU GHIHFW GHIHFW ZKLFK RULJLQDWHV

GXH WR KLJK KHDW LQSXW )XUWKHUPRUH WKHUH LV QR QDUURZ

JDS LV QRW IRUPHG DQG WKH ZHOGLQJ SRLQW LV IRUPHG

QHDU WKH 9 FRQYHUJHQFH SRLQW )RUPDWLRQ RI WKLV GHIHFW

LV DFFRPSDQLHG E\ DQ R[LGH LQFOXVLRQ LQ D IRUP RI

FRQWLQXRXV WKLQ ¿OP DW WKH ZHOGPHQW 7KLV UHVXOW GXH

WR OHVV KHDW LQSXW SRZHU LQWR WKH VWULS ZKLFK VLJQL¿HV

LQDGHTXDWH PHOWLQJ RI WKH VWULS HGJHV :KHQ RQO\ D

YHU\ WKLQ VXUIDFH OD\HU RI WKH HGJH LV PHOWHG ZLWK DQ

LQVXႈFLHQW KHDW LQSXW SRZHU R[LGHV RQ WKH VXUIDFHV

PD\ QRW EH VTXHH]HG RXW DORQJ ZLWK WKH PROWHQ PHWDO

DW WKH XSVHWWLQJ VWDJH OHDGLQJ WR WKH FROG ZHOG GHIHFW

7KH IUDFWXUHG VXUIDFH RI FROG ZHOG GHIHFW JHQHUDOO\

UHYHDOV WKDW (5: MRLQW LV ÀDW DQG VPDOO DQG WKLQ R[LGHV

)LJ 6FKHPDWLFV RI HGJH SUHSDUDWLRQ IRU W\SH $ % DQG & DUH HYHQO\ GLVWULEXWHG RQ WKH VXUIDFH 7KHVH R[LGHV

STEEL TECH