Page 20 - Steel Tech India eMagazine Volume January 2023

P. 20

92/ Ć ,668( Ć 2FWREHU

(OHFWULFLW\ EDVHG PHWDOOXUJ\ ZKLFK XVHV HOHFWULFLW\ that in order to reduce carbon dioxide emissions from

instead of carbon as reduction agent for the iron ore steel production to near zero, alternative steelmaking

reduction, with greater focus on renewable energy. processes (hydrogen direct reduction, steel electrolysis)

6SHFL¿F SURSRVDOV RI ORZ FDUERQ WUDQVLWLRQ RI VWHHO need to be developed while CO reduction in short-term

2

industry envisaged by some countries (heat recovery, scrap usage and the use of by-products

to produce base chemicals) need to be realized in time

General approach towards gradual decarbonization bound manner.

for the energy intensive industries have mostly

been reported around three broad themes- Although the above works give important knowledge on

L GHPDWHULDOL]DWLRQ RU UHF\FOH UHXVH LL VXEVWDQWLDO the available options for abatement of carbon emissions

changes of existing processes, (iii) maintaining existing from steel production, there exists lack of studies which

processes with CCS or using an alternative heat source. shows how a transition from today’s steel industry to

a near zero-emitting steel industry could be achieved

In the most comprehensive evaluation reported, that over time.

has been carried out by Swedish steel industry, it has

been concluded that in order to reach deep emissions A Practicable Framework

FXWV HႈFLHQW HQHUJ\ XVH PXVW EH FRPELQHG ZLWK Based on the current structure and projected pattern

alternative technologies such as fuel replacement and RI VWHHO LQGXVWU\ D VLJQL¿FDQW QXPEHU RI DSSURDFKHV

&&6 7KH ¿QGLQJV DOVR VKRZ WKH FKDOOHQJHV LQYROYHG LQ have been reported by various entities. It is expected

WKH FRQWH[W RI VSHFL¿F FDVH XVLQJ ELRPDVV WR UHSODFH WKDW %) %2) URXWH ZLOO UHPDLQ VLJQL¿FDQW PRGH RI

coal in one single blast furnace would decrease the CO production in steel industry in foreseeable future. From

2

emissions of the Swedish steel industry by 17.3%. This this perspective, BHP’s three stage decarbonization

theoretical exercise apparently assumes that there are framework appears to be best suited for Steel Industry

no technological challenges involved in such a case, for gradual transition. Table 1 gives a snapshots of

which is highly unlikely from a practical perspective. this approach. It is possible for each steel plant to

Even in such an ideal scenario, this would require customize their own practicable approach based on this

6.19 TWh of biomass, which correspond to about 4% generalized framework.

of annual (2017) biomass harvests from the Swedish Within the optimization and transition stage, there are

forest industry, while there are several sectors that several strategies and technologies that is possible

compete over the biomass resource.

and has often been proposed to be deployed in

,GHQWL¿HG IXWXUH SDWKZD\V WRZDUGV D ORZ FDUERQ varying extents to reduce CO emissions from existing

2

steel production industry in Germany up to 2035 lays infrastructure:

emphasis on estimating technical options towards &RQVFLRXV HDUO\ UHWLUHPHQW RU LQWHULP XQGHU XWLOLVDWLRQ

UHGXFLQJ VSHFL¿F HQHUJ\ FRQVXPSWLRQ DQG &2

2 of plant units, either because of a change in policy

emissions in the steel industry. It has been concluded

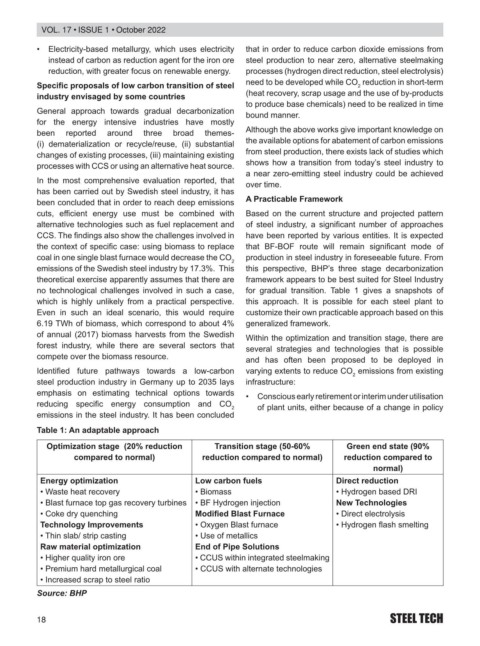

Table 1: An adaptable approach

Optimization stage (20% reduction Transition stage (50-60% Green end state (90%

compared to normal) reduction compared to normal) reduction compared to

normal)

Energy optimization Low carbon fuels Direct reduction

:DVWH KHDW UHFRYHU\ %LRPDVV +\GURJHQ EDVHG '5,

%ODVW IXUQDFH WRS JDV UHFRYHU\ WXUELQHV %) +\GURJHQ LQMHFWLRQ New Technologies

&RNH GU\ TXHQFKLQJ 0RGL¿HG %ODVW )XUQDFH 'LUHFW HOHFWURO\VLV

Technology Improvements 2[\JHQ %ODVW IXUQDFH +\GURJHQ ÀDVK VPHOWLQJ

7KLQ VODE VWULS FDVWLQJ 8VH RI PHWDOOLFV

Raw material optimization End of Pipe Solutions

+LJKHU TXDOLW\ LURQ RUH &&86 ZLWKLQ LQWHJUDWHG VWHHOPDNLQJ

3UHPLXP KDUG PHWDOOXUJLFDO FRDO &&86 ZLWK DOWHUQDWH WHFKQRORJLHV

,QFUHDVHG VFUDS WR VWHHO UDWLR

Source: BHP

STEEL TECH