Page 23 - Steel Tech India eMagazine Volume January 2021

P. 23

81. Ŗ 01 Ŗ ,CPWCT[

Fig. 4: Production of DRI worldwide

Conversion from BF-BOF to DRI-EAF: Challenges load of a large electric arc furnace and to tolerate the

and Constraints disturbances induced by this machine.

Beyond the obvious consideration of capital Let’s consider a DRI-EAF line worth producing 2.5

expenditures, the transformation of existing integrated Mt per year of DRI. The size of the transformer

cycle facilities into DRI-based operations poses several required to feed such a productive machine is 200-

EJCNNGPIGU VJG ſTUV DGKPI VJG CXCKNCDKNKV[ QH C RQYGT 250MVA (depending on the chemistry of the pellets

FKUVTKDWVKQP ITKF YKVJ UWHſEKGPV ECRCEKV[ VQ UWUVCKP VJG and feeding temperature), with a peak load of about

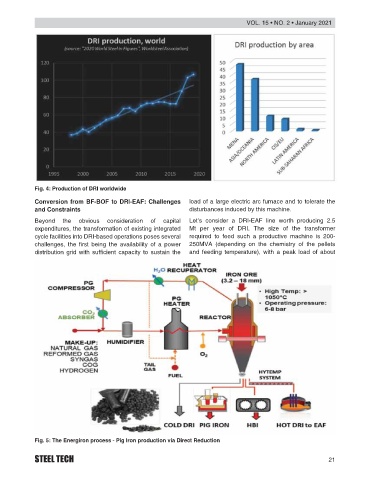

Fig. 5: The Energiron process - Pig Iron production via Direct Reduction

STEEL TECH 21