Page 21 - Steel Tech India eMagazine Volume January 2021

P. 21

81. Ŗ 01 Ŗ ,CPWCT[

Engineering the Green Revolution of

Ironmaking – A Minimally Impacting Route to

the De-Carbonisation of Existing Ironmaking

Plants

1

2

Paolo STAGNOLI , Andre ESTERHUIZEN and Praveen CHATURVEDI 3

3

1 Tenova SpA, ITALY, Tenova Pyromet, SOUTH AFRICA and Tenova Technologies Pvt Ltd, INDIA

2

INTRODUCTION

Steel, unlike many other structural materials such as

EQPETGVG QT GXGP RQN[OGTU KU CP KPFGſPKVGN[ TGE[ENCDNG

material that can be used, re-molten and re-used

YKVJQWV NQUU QH SWCNKV[ CPF YKVJ CP GHſEKGPE[QH

depending on applications. Steel is everywhere in

everybody’s life: vehicles, house appliances, buildings,

bridges, rails are only examples of the countless steel

applications. Steel is undoubtedly one of the pillars of

the transition from a linear to a circular economy. In

2019, the world produced 1,86bn tons of steel (about

ten times more than in 1950), and the World Steel

Association predicts the production to reach 2,7bn in

2050.

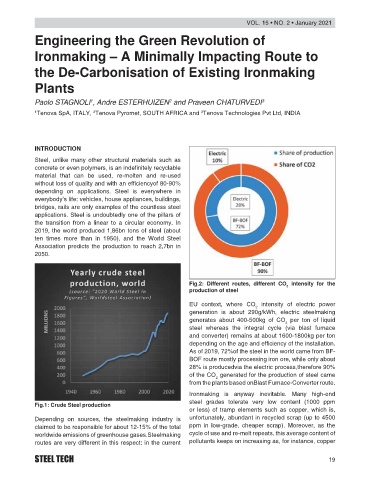

Fig.2: Different routes, different CO intensity for the

2

production of steel

EU context, where CO intensity of electric power

2

generation is about 290g/kWh, electric steelmaking

generates about 400-500kg of CO per ton of liquid

2

steel whereas the integral cycle (via blast furnace

and converter) remains at about 1600-1800kg per ton

FGRGPFKPI QP VJG CIG CPF GHſEKGPE[ QH VJG KPUVCNNCVKQP

As of 2019, 72%of the steel in the world came from BF-

BOF route mostly processing iron ore, while only about

28% is producedvia the electric process,therefore 90%

of the CO generated for the production of steel came

2

from the plants based onBlast Furnace-Converter route.

Ironmaking is anyway inevitable. Many high-end

steel grades tolerate very low content (1000 ppm

Fig.1: Crude Steel production

or less) of tramp elements such as copper, which is,

Depending on sources, the steelmaking industry is unfortunately, abundant in recycled scrap (up to 4500

claimed to be responsible for about 12-15% of the total ppm in low-grade, cheaper scrap). Moreover, as the

worldwide emissions of greenhouse gases.Steelmaking cycle of use and re-melt repeats, this average content of

routes are very different in this respect: in the current pollutants keeps on increasing as, for instance, copper

STEEL TECH 19