Page 39 - Steel Tech India eMagazine Volume October 2021

P. 39

92/ Ć 12 Ć 2FWREHU

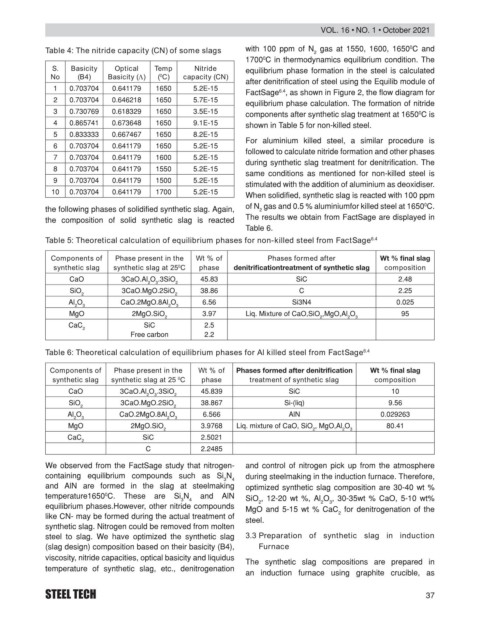

Table 4: The nitride capacity (CN) of some slags ZLWK SSP RI 1 JDV DW & DQG

& LQ WKHUPRG\QDPLFV HTXLOLEULXP FRQGLWLRQ 7KH

S. Basicity Optical Temp Nitride HTXLOLEULXP SKDVH IRUPDWLRQ LQ WKH VWHHO LV FDOFXODWHG

0

No (B4) Basicity (/) ( C) capacity (CN)

DIWHU GHQLWULILFDWLRQ RI VWHHO XVLQJ WKH (TXLOLE PRGXOH RI

(

)DFW6DJH DV VKRZQ LQ )LJXUH WKH IORZ GLDJUDP IRU

(

HTXLOLEULXP SKDVH FDOFXODWLRQ 7KH IRUPDWLRQ RI QLWULGH

(

FRPSRQHQWV DIWHU V\QWKHWLF VODJ WUHDWPHQW DW & LV

( VKRZQ LQ 7DEOH IRU QRQ NLOOHG VWHHO

(

)RU DOXPLQLXP NLOOHG VWHHO D VLPLODU SURFHGXUH LV

(

IROORZHG WR FDOFXODWH QLWULGH IRUPDWLRQ DQG RWKHU SKDVHV

(

GXULQJ V\QWKHWLF VODJ WUHDWPHQW IRU GHQLWULILFDWLRQ 7KH

(

VDPH FRQGLWLRQV DV PHQWLRQHG IRU QRQ NLOOHG VWHHO LV

(

VWLPXODWHG ZLWK WKH DGGLWLRQ RI DOXPLQLXP DV GHR[LGLVHU

(

:KHQ VROLGLILHG V\QWKHWLF VODJ LV UHDFWHG ZLWK SSP

WKH IROORZLQJ SKDVHV RI VROLGLILHG V\QWKHWLF VODJ $JDLQ RI 1 JDV DQG DOXPLQLXPIRU NLOOHG VWHHO DW &

WKH FRPSRVLWLRQ RI VROLG V\QWKHWLF VODJ LV UHDFWHG 7KH UHVXOWV ZH REWDLQ IURP )DFW6DJH DUH GLVSOD\HG LQ

7DEOH

Table 5: Theoretical calculation of equilibrium phases for non-killed steel from FactSage 6.4

Components of Phase present in the Wt % of Phases formed after :W ¾QDO VODJ

0

synthetic slag synthetic slag at 25 C phase GHQLWUL¾FDWLRQWUHDWPHQW RI V\QWKHWLF VODJ composition

&D2 &D2 $O 2 6L2 6L&

6L2 &D2 0J2 6L2 &

$O 2 &D2 0J2 $O 2 6L 1

0J2 0J2 6L2 /LT 0L[WXUH RI &D2 6L2 0J2 $O 2

&D& 6L&

)UHH FDUERQ

Table 6: Theoretical calculation of equilibrium phases for Al killed steel from FactSage 6.4

Components of Phase present in the Wt % of 3KDVHV IRUPHG DIWHU GHQLWUL¾FDWLRQ :W ¾QDO VODJ

synthetic slag synthetic slag at 25 C phase treatment of synthetic slag composition

0

&D2 &D2 $O 2 6L2 6L&

6L2 &D2 0J2 6L2 6L OLT

$O 2 &D2 0J2 $O 2 $O1

0J2 0J2 6L2 /LT PL[WXUH RI &D2 6L2 0J2 $O 2

&D& 6L&

&

:H REVHUYHG IURP WKH )DFW6DJH VWXG\ WKDW QLWURJHQ DQG FRQWURO RI QLWURJHQ SLFN XS IURP WKH DWPRVSKHUH

FRQWDLQLQJ HTXLOLEULXP FRPSRXQGV VXFK DV 6L 1 GXULQJ VWHHOPDNLQJ LQ WKH LQGXFWLRQ IXUQDFH 7KHUHIRUH

DQG $O1 DUH IRUPHG LQ WKH VODJ DW VWHHOPDNLQJ RSWLPL]HG V\QWKHWLF VODJ FRPSRVLWLRQ DUH ZW

WHPSHUDWXUH & 7KHVH DUH 6L 1 DQG $O1

6L2 ZW $O 2 ZW &D2 ZW

HTXLOLEULXP SKDVHV +RZHYHU RWKHU QLWULGH FRPSRXQGV

0J2 DQG ZW &D& IRU GHQLWURJHQDWLRQ RI WKH

OLNH &1 PD\ EH IRUPHG GXULQJ WKH DFWXDO WUHDWPHQW RI

VWHHO

V\QWKHWLF VODJ 1LWURJHQ FRXOG EH UHPRYHG IURP PROWHQ

VWHHO WR VODJ :H KDYH RSWLPL]HG WKH V\QWKHWLF VODJ 3.3 Preparation of synthetic slag in induction

VODJ GHVLJQ FRPSRVLWLRQ EDVHG RQ WKHLU EDVLFLW\ % Furnace

YLVFRVLW\ QLWULGH FDSDFLWLHV RSWLFDO EDVLFLW\ DQG OLTXLGXV

7KH V\QWKHWLF VODJ FRPSRVLWLRQV DUH SUHSDUHG LQ

WHPSHUDWXUH RI V\QWKHWLF VODJ HWF GHQLWURJHQDWLRQ

DQ LQGXFWLRQ IXUQDFH XVLQJ JUDSKLWH FUXFLEOH DV

STEEL TECH