Page 15 - Steel Tech India eMagazine Volume January 2021

P. 15

81. Ŗ 01 Ŗ ,CPWCT[

bring down its carbon footprint by improving resource world can change course to deliver on the main energy-

GHſEKGPE[ CPF CFQRVKQP QH DGUV CXCKNCDNG VGEJPQNQIKGU related Sustainability Development Goals (SDGs).

Tata Steel Jamshedpur is the Indian benchmark for CO As shown in Fig. 3, the IEA scenario based modelling

2

emission intensity at 2.27 tCO /tcs and has reduced from predicts that CO intensity of steel will come down,

2 2

3.12 tCO VEU KP NCUV [GCTU YKVJ UKIPKſECPV %#2': however it will not become zero by 2050 even in SDS

2

investments to adopt best available technologies. scenario.

Fig. 2: Tata Steel India’s journey to decarbonisation

TSI has been working with Government agencies and

policy think-tanks to push for policy changes to support

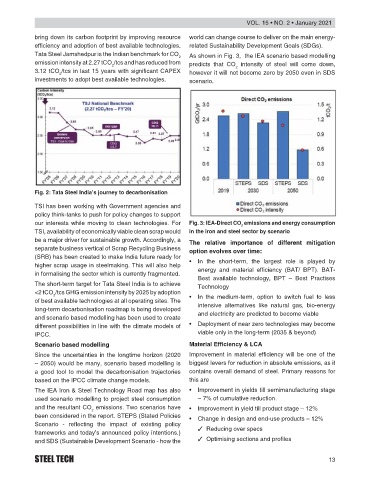

our interests while moving to clean technologies. For Fig. 3: IEA-Direct CO emissions and energy consumption

2

TSI, availability of economically viable clean scrap would in the iron and steel sector by scenario

be a major driver for sustainable growth. Accordingly, a The relative importance of different mitigation

separate business vertical of Scrap Recycling Business option evolves over time:

(SRB) has been created to make India future ready for

higher scrap usage in steelmaking. This will also help Ŗ +P VJG UJQTV VGTO VJG NCTIGUV TQNG KU RNC[GF D[

in formalising the sector which is currently fragmented. GPGTI[ CPF OCVGTKCN GHſEKGPE[ $#6 $26 $#6

Best available technology, BPT – Best Practises

The short-term target for Tata Steel India is to achieve Technology

<2 tCO /tcs GHG emission intensity by 2025 by adoption

2 Ŗ +P VJG OGFKWO VGTO QRVKQP VQ UYKVEJ HWGN VQ NGUU

of best available technologies at all operating sites. The

long-term decarbonisation roadmap is being developed intensive alternatives like natural gas, bio-energy

and scenario based modelling has been used to create and electricity are predicted to become viable

different possibilities in line with the climate models of Ŗ &GRNQ[OGPV QH PGCT \GTQ VGEJPQNQIKGU OC[ DGEQOG

IPCC. viable only in the long-term (2035 & beyond)

Scenario based modelling 0DWHULDO (IÀFLHQF\ /&$

Since the uncertainties in the longtime horizon (2020 +ORTQXGOGPV KP OCVGTKCN GHſEKGPE[ YKNN DG QPG QH VJG

– 2050) would be many, scenario based modelling is biggest levers for reduction in absolute emissions, as it

a good tool to model the decarbonisation trajectories contains overall demand of steel. Primary reasons for

based on the IPCC climate change models. this are

The IEA Iron & Steel Technology Road map has also Ŗ +ORTQXGOGPV KP [KGNFU VKNN UGOKOCPWHCEVWTKPI UVCIG

used scenario modelling to project steel consumption – 7% of cumulative reduction.

and the resultant CO emissions. Two scenarios have Ŗ +ORTQXGOGPV KP [KGNF VKNN RTQFWEV UVCIG Ō

2

been considered in the report. STEPS (Stated Policies Ŗ %JCPIG KP FGUKIP CPF GPF WUG RTQFWEVU Ō

5EGPCTKQ TGƀGEVKPI VJG KORCEV QH GZKUVKPI RQNKE[ Reducing over specs

frameworks and today’s announced policy intentions.)

and SDS (Sustainable Development Scenario - how the 1RVKOKUKPI UGEVKQPU CPF RTQſNGU

STEEL TECH 13